Laboratories based learning with academic support throughout sessions. Structure is tutorial together with hands on practical work. Students have to issue a 3,000-word review to include the following: document laboratory results describing the steps taken to achieve final results. Then describe possible sources of error or misinterpretation that may have impacted results.

LocationCranfield LeaderMr Paul Morantz |

Structure16 hours laboratory + 16 hours independent learning time and 16 hours written assignment AssessmentCoursework worth 15 credits |

Objectives

On successful completion of this study the student should be able to:

Modal Analysis:

- Understand modal analysis principles

- Use modal testing equipment at a basic level

- Complete rapid assessment of machine tool dynamic performance

Test & Measurement:

- Introduction to surface measurement instrumentation

- Insight into parameters used to qualify surface texture

- Introduction to form measurement instrumentation

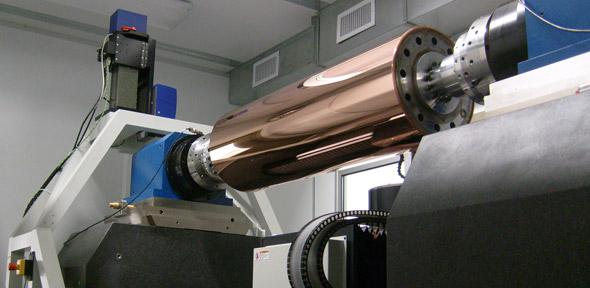

Single Point Diamond Turning:

- Introduction to “state of the art” high precision machines

- Provide insight into parameters that effect surface generation

- Gain insight into programming of machine tools

Essential reading

- Precision Engineering Module, CIM-UP MRes course – “Assessment of Machine Tool Dynamic Performance”

- Handbook of Surface Metrology, David J Whitehouse, IOP publishing, ISBN 0-7503-0039-6

- Metal Cutting Principles, Milton Shaw, Oxford University Press 2005, ISBN 0-19-514206-3