High precision manufacturing of components at micro and millimetre scale often require multiplatform manufacturing which may involve various additive and subtractive manufacturing. The quality of such products relies on traceable high accuracy shop floor measuring instruments. Traceability of such instruments is limited to basic calibration routines that certify the axis of the machines, however, this is not enough for the measurement of complex parts with inherited micro geometry.

StudentSupervisor |

Sponsor |

To overcome such limitations, a functional calibration of the measurement instruments is often required which implies calibration of reference artefacts with challenging geometries that equality possess challenging forms and micro structures. To produce such artefacts requires tools akin to high precision manufacturing.

Aim

To develop manufacturing process chains for bespoke and mass production of reference artefacts used to assure traceability of high precision manufacturing of components at micro and millimetre scale.

The main objectives are:

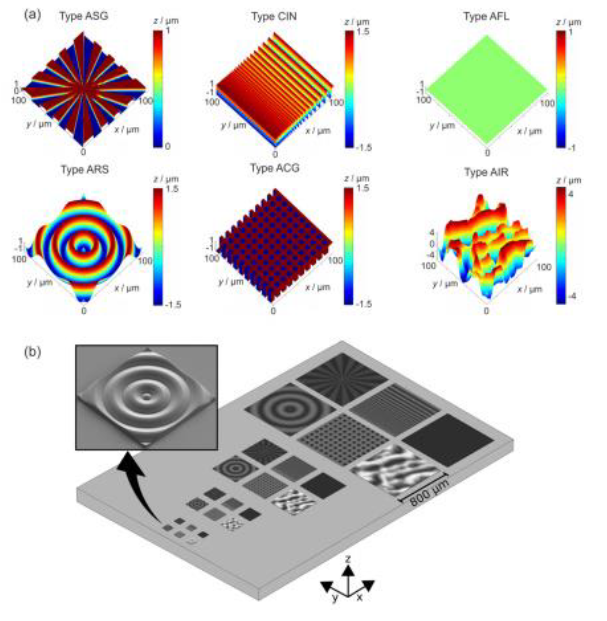

- Propose design of new artefacts 2D and 3D artefacts with critical features laying in sub-micrometre to millimetre domain.

- Develop cost effective manufacturing process based on conventional precision single point diamond turning and micro-milling techniques.

- Develop techniques to manufacture superimposed structures with critical lateral dimensions varying from 200 nm to 1 mm.

- Produce prototypes and validate their metrological characteristics.

Artefacts examples