The fabrication of superhydrophobic surfaces is the focus of intense research globally. There are many potential applications for the technology because of the potential to accurately channel water, reduce corrosion, reduce cleaning cycles and therefore water consumption and to possibly reduce the adhesion of biological contamination. Additional applications of interest include biomedical diagnostics, micro fuel cells and water harvesting devices but these all call for the development of patternable wettability control.

StudentSupervisors |

Partners and Sponsors |

Introduction

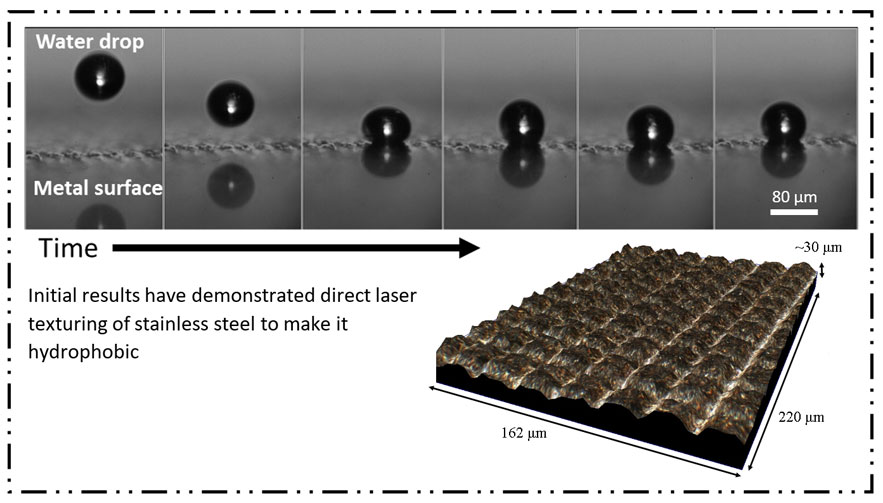

The potential for superhydrophobicity and other functionalities has been successfully demonstrated at the laboratory scale, many of these processes have involved non-scalable fabrication techniques with the use of specialized reagents, harsh conditions and relatively high costs. Part of this study will investigate direct laser texturing of sheet material for the fabrication of superhydrophobic surfaces, this process imparts superhydrophobicity through inherent modification of the surface texture and chemistry without the use of coatings. This process has proven capable of producing some of the most strongly nonwetting surfaces ever created with key benefits of low cost, scalability and HSE neutrality.

Further work will investigate hybrid techniques of laser processing with digitally enabled additive coatings, advanced substrate materials and novel surface multifunctionality. Targeted surface functionalities will involve patterned or switchable wettability, optical properties, oleophobicity and bacterial anti-adhesion.

Approach

Four key deliverables have been forecast for the first year of the project.

- Expand on the work of the MRes long project ‘Wide area laser manufacturing of self-cleaning surfaces’. This work will aim to test the viability of different materials and the development of laser process conditions for industrial adoption.

- A comprehensive literature review of the field ‘Laser processed superhydrophobic surfaces’.

- A standalone experimental investigation which assesses the durability and longevity of the laser induced surface modification in comparison to alternative approaches.

- The design and initial testing of a hybrid processing technique to impart novel surface properties or functions.

Partners and Sponsors

Worshipful Company of Engineers - engineerscompany.org.uk

Thurne – Manufacturer of industrial high-speed slicing equipment - www.thurne.com

Pilkington – Multinational glass manufacturer who innovated the float glass process and selfcleaning glass – www.pilkington.com

SPI Lasers – A leading manufacturer of pulsed and CW fibre lasers for a wide range of industries including automotive, electronics and the medical device sectors. – www.spilasers.com