Coatings on the cutting tools is a long last sustainable business area and hence they need better and more accurate real time assessment methods of fracture toughness – an important property driving wear of coatings beside hardness and elastic modulus.

StudentSupervisor |

In this proposal, the primary interest is to work towards the development of a testbed that would allow assessment of mechanical properties (fracture toughness, elastic modulus and hardness) of coatings - from a commercial standpoint as to how to quickly discover which coating material will provide longer lifetime when put in service. In light of this, the proposal discusses a technical method of determining fracture toughness of coatings with least uncertain value.

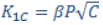

Fracture toughness of a material is its resistance to the propagation of cracks. It is general obtained by an expression that links, the applied load, the crack length and the specimen geometry:

(1)

(1)

where β is a specific geometry constant, P is the applied load and c is the crack length.

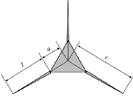

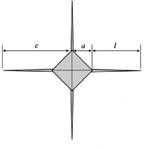

One simple way to measure fracture toughness of a thin film is by using indentation cracking method [1]. This method relies on using a sharp indenter to augment high shear stress (stress intensity exceeding the energy release rate of the specimen material) via a three-sided pyramidal or a four-sided prismatic indenter that helps to introduce radial cracks on the surface of the material (shown in figure 1). With the advances in instrumentation, it is in fact possible to study crack growth in a specimen as a function of applied load (and at the same time to extract elastic modulus (E) of the material using continuous stiffness method (CSM) and estimating hardness (H) of the specimen.

|

Berkovich where a=65.03° |

Cube corner where a=35.26° |

|

(a) Sharp 3-sided pyramidal indenters and the triangular cracking pattern they introduce

|

Vickers where a=68° |

Knoop where d=172.5° and g=130 |

|

(b) Sharp 4-sided prismatic indenters and the cubic cracking pattern they introduce

Figure 1: Various kinds of three-sided and four-sided indenters used in the literature on indentation