This project aims to improve the reliability of AM processes perform in process monitoring with a novel multi-sensory system that is integrated into the build chamber.

StudentSupervisorSimon Lawes |

Additive manufacturing has huge potential in a wide variety of fields due to its tool free manufacturing capabilities and freedom in component geometries when compared to traditional subtractive manufacturing. Regardless of this fact, AM has still a strong drive for greater adoption in industries such as medical and aerospace due to these sectors requiring high levels of confidence in the structural quality of their parts which AM is not yet capable of supplying. Current methods of testing AM parameters and component build quality relies of post process analysis of manufactured parts through both destructive and non-destructive methods which is both costly and time consuming.

Additive manufacturing has huge potential in a wide variety of fields due to its tool free manufacturing capabilities and freedom in component geometries when compared to traditional subtractive manufacturing. Regardless of this fact, AM has still a strong drive for greater adoption in industries such as medical and aerospace due to these sectors requiring high levels of confidence in the structural quality of their parts which AM is not yet capable of supplying. Current methods of testing AM parameters and component build quality relies of post process analysis of manufactured parts through both destructive and non-destructive methods which is both costly and time consuming.

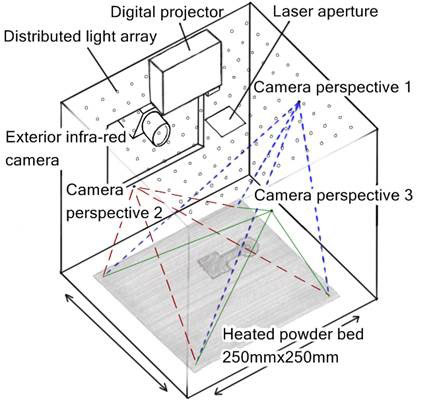

This project aims to improve the reliability of AM processes perform in process monitoring with a novel multi-sensory system that is integrated into the build chamber. The system will make use of deflectometry, photogrammetry and fringe projection during the build process. This will allow for topographical information to be acquired for individual layers of the part being processed so that out of tolerance features can be recognised and parameter alterations can be made for the following layers to ensure part quality remains consistent.